There are a million ways to plumb a sink drain incorrectly, and it’s almost always the result of ignorance. It’s not stupidity or malice; it’s just a lack of knowledge. And most of the time, these improper installations work pretty ok as long as they don’t leak. As home inspectors, we typically point out these improper installations and explain why they matter.

One common error we find under sinks is a double trap; this happens when water drains through two separate traps, as shown in the examples below.

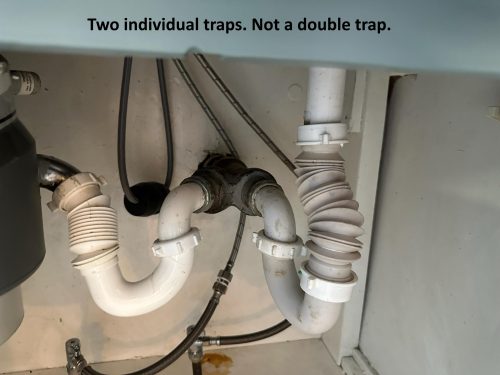

In all of these cases, water has to pass through two separate traps, called a double trap. But don’t confuse this with two separate traps, which is fine.

Of course, those corrugated things in the photo above aren’t proper, but the configuration is correct.

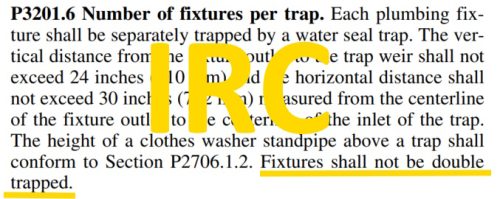

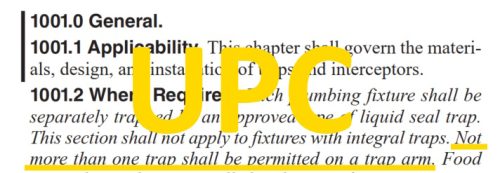

Plumbing codes expressly prohibit the use of double traps.

But what’s the problem with this setup? I’ve been told that this will cause the sink to drain slower, increasing the potential for the trap to get clogged. I’ve also heard that you end up trapping a column of air between the two traps, which will mess with the drain performance. But I’ve never known for sure, so I decided to do my own test.

Testing a double-trap

To test the difference in performance between a standard p-trap and a double trap, I set up a pedestal sink in my backyard.

I filled the sink with water and let it drain twice, once with a single trap and once with a double trap. My results from the two tests were nearly identical. The water took the same amount of time to drain for both tests. So, there goes my theory of a double-trap draining slower, thus increasing the potential for clogs.

One interesting thing I found was that the second trap created a siphon, sucking some water out of the first trap. This would normally be concerning, but the second trap was still filled with water.

Conclusion

Sorry, I don’t have anything exciting to report. At this point, I’m not sure why the plumbing code doesn’t allow two traps. We’ll continue to report this as an improper installation, but I’m not sure what the big consequence is.

If any smart readers out there know the real answer, please comment. I’m genuinely curious.

Tim LaPara

June 26, 2024, 7:14 am

My father-in-law claimed that he knew basic plumbing “helped” me install a garbage disposal once. It involved a double trap. The disposal worked okay but the trap would occasionally clog. A few years later after I learned some plumbing skills of my own, I re-did the plumbing correctly. The p-trap never clogged after that.

Manny Manzano

July 26, 2024, 7:44 am

Hi. First I would like to make a correction to a photo above. The photo with two individual traps is actually a double trap, arranged in parallel. Minnesota Plumbing Code (MPC) considers a sink to be a single fixture per Table 702.1 – see “Sink, Kitchen, domestic with or without food waste grinder”. A single trap arm serves that fixture. A trap arm is the pipe sticking out of the wall that joins the fixture’s trap to the fixture’s vent pipe. As such, each individual fixture is permitted to have a single trap per trap arm under MPC 1001.2 – “Not more than one trap shall be permitted on a trap arm”. So it is MPC 1001.2 that prohibits multiple traps per trap arm, whether they are in a series, or in parallel. If you are going to join two, or three, basins at the same level of a sink together upstream of a trap, you must use a continuous waste assembly. Side note, you are also permitted to gang 2 or 3 lavatories together with a continuous waste and have a single trap and trap arm serve all 3 per MPC 1001.2. —- But you also ask “why” this is not permitted. That is a different question. With traps in series, it’s pretty simple. The maximum distance between a trap and its vent is fixed per MPC table 1002.2. This distance is important so as to maintain a proper hydraulic gradient. What I mean by that is that we never want a condition where the crown weir of a trap (the bottom side of the trap’s outlet) to be above the opening of the vent. So since MPC 1003.3 requires that a trap be the same size as a the trap arm, and Table 1002.2 requires that trap arms be sloped at 1/4″ per foot, you can do the math and see that the code is keeping us from flooding out our vent openings. Example: a 2″ trap arm is 60″ (5′) max trap to vent. 5′ x 1/4″ per foot = 1-1/4″ of total pitch over the run. That leaves a minimum nominal air space of at least 3/4″ at the joint between the trap arm and the vent if we have a 5′ long trap arm on a 2″ trap. (I say nominal because the real inside diameter of any given pipe varies a bit with it’s material type. For PVC it is 2.047″) In other words, since we rely on the vent to break a potential siphon, we cannot have a condition where the flow of water completely submerges the opening of the vent. My instinct is that that was figured out by Dr. Roy Hunter way back in the 1920s when he was doing the first tests on traps, vents, and all of that. Dr. Hunter was trying to determine under what conditions a trap would hold it’s seal against the wild fluctuations of water flowing and churning around inside of a piping system with people using toilets and sinks and tubs all at random times and intermittent intervals. The whole purpose of a trap is to maintain a minimum trap seal in a plumbing system so as not to allow sewer gasses into a building and poison people. If you notice, code requires a final plumbing test to hold pressure against a pressure of 1″ of water column. But a trap seal is required to be 2″ deep minimum per MPC 1005.1. That 2″ of trap seal depth is really a 2x safety factor. —- As for 2 traps at a single fixture arranged in parallel, I do not have an engineering answer for that one. I don’t know that there really is a problem with it. As a plumber, I saw 10,000 kitchen sinks installed that way across this city. I did it myself countless times over the years. When I was an Apprentice and Journeyman, my Master Plumber would tell us to do it that way. I certainly don’t do it anymore. Anecdotely, I recall that back in the mid 2000s code officials started getting extra picky about it. Nowadays it has pretty much disappeared as a thing as far as I know, especially if a code official is coming out and inspecting your work.

Reuben Saltzman

July 29, 2024, 10:27 am

Manny – WOW. This is a very helpful response. Thank you so much for taking to time to chime in. I appreciate it.

Morgan Cohen

September 8, 2024, 7:50 am

Love the discussion on topics we always come across. Manny that was a great explanation, and thanks for explaining the traps in parallel!