Moisture testing on relatively newer stucco houses (mid 1980s – late 2000s) has become standard practice when buying a home in Minnesota, and a lot of those tests reveal problems with moisture intrusion. Water intrusion is never good news, but it is important to know there are options to consider when exploring a repair strategy for a home with water damage.

Remediation protocols range from retrofit, which consists of partial repair and maintenance, to full tear off and replacement. A full tear-off and replace means removing all of the stucco and replacing with an alternate cladding material, such as James Hardie HardiePlank® or LP Smartside®. Today, we’ll be taking a closer look at a retrofit repair by Sunset Construction Group (SunsetCG), a Minnesota company that specializes in repairing stucco houses with moisture intrusion problems.

When SunsetCG is contacted to perform stucco repairs on an existing home, there are four basic steps that take place; a review of the moisture testing report, removal of the stucco at the affected areas, repair of the affected areas, and maintenance on the rest of the stucco. Today, we’ll take a closer look at a home that SunsetCG performed repairs on.

Review the Moisture Testing Report

The first thing SunsetCG wants to see is the moisture testing report, which is what we provide. This report will contain photos of the home along with moisture readings, which helps to determine the scope of the work and offers professional guidance to the buyer and sellers of a property. From there, a bid is put together on stucco repairs and various repair strategies are explored.

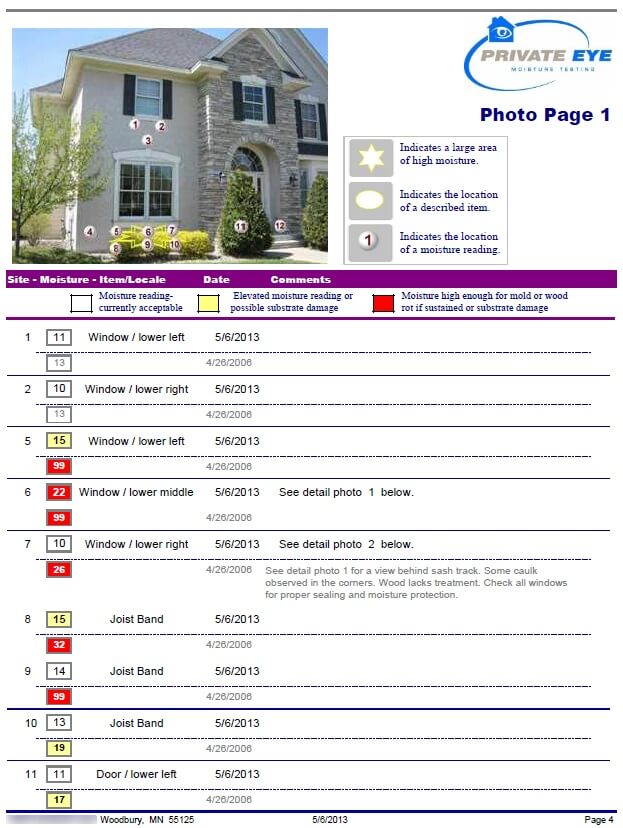

Reviewing this retrofit-level case study, we first performed moisture testing at this home in 2006, and found several areas with high moisture levels, but no repairs were conducted at that time. We performed moisture testing again in 2013, and many of those same areas showed high levels of moisture, so SunsetCG was contacted to perform repairs.

Here’s an excerpt from our moisture testing report, showing exactly which areas of the wall sheathing had elevated moisture levels; our results from 2006 and 2013 are documented right next to each other on the report for comparison.

To keep this short, I’m only focusing on a small portion of the house.

Partial Stucco Removal

As you can see from the moisture testing report above, the big area of concern was directly below the first floor window. The next step was to have a minimal amount of stucco removed around the window, to expose and give access to the water damaged areas. Click the photo for a larger version.

Stucco Repair

After the stucco was removed, the source and severity of the moisture intrusion were confirmed. The sheathing, framing, and insulation of the impacted areas were repaired or replaced as needed. The impacted areas were then redesigned using improved materials and installation methods, to highly reduce the potential for future moisture problems.

Examples of new materials and methods would be new head flashing above the window and new pan flashing below the window.

The stucco color and texture were then patched and matched as closed as possible, and then the front of the house was painted with a high quality, breathable stucco paint to give the front of the house a uniform look.

Stucco Maintenance

While existing stucco homes may not have been constructed with the same details that a new stucco house would be built with today, the areas that have proven to perform over the years are maintained in their current condition with a quality caulk/seal effort. Some areas of particular attention will be the window miters, mullions and perimeter of windows, and vertical transitions between stucco and other surfaces, such as windows and doors.

The theory/risk proposition with a retrofit repair is that the areas that have performed over the past ten to fifteen years will probably continue to perform, even though it may not be an ideal installation. The main benefit with this type of repair is cost; these types of repairs will typically cost 30% – 40% of what a full tear off and redo would be.

When a retrofit repair is performed, a follow-up moisture testing inspection should take place three to five years after the repairs have taken place.

Along with the lower cost of repairs comes a limited warranty on the work. A ten year warranty (per MN State Statute) is not likely to apply under most (if not all) retrofit repair strategies, as the contractor is only touching part of a wall. If a ten year warranty is a must, other repair strategies are available and will be covered in future blog posts.