Never skip the home inspection, even if the house is brand new. I don’t care what the builder tells you; you need a home inspection. There’s too much at stake, too much that can go wrong, and too much gets missed with municipal inspections.

I’m not knocking municipal (city/county/AHJ) inspectors; I have extremely high respect for them and couldn’t do what they do. But they don’t do home inspections, and it’s not the same thing. We inspect hundreds of new construction houses every year, and we continually find problems with new homes. As long as there is the potential for human error in the construction of a home, there will be a need for home inspections.

But don’t take my word for it; please check out these photos from the past year to see what I mean. To start off, I have a rather long case study. Check out the sag in the ridge line of this roof.

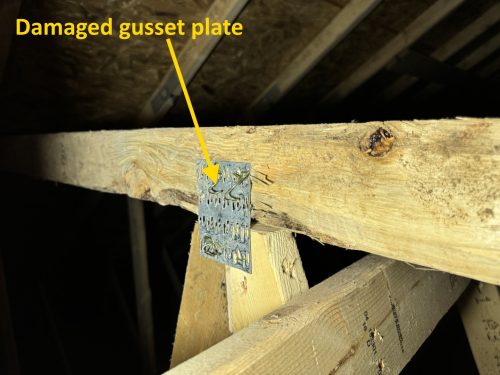

The attic was sealed shut, and the builder didn’t permit us to open it, so we couldn’t see exactly what caused this. Our recommendation was to make the attic accessible and have it inspected by a qualified person. The builder made some makeshift repairs to the roof structure, and we went out a second time to inspect the repairs. The photos below show what we found after we were given access to the attic space.

Remember, this is what we found after the builder had supposedly fixed the problems with the trusses. As a general rule, if you’re going to make repairs to a truss, the repairs need to come from the manufacturer or an engineer. The repairs will include detailed drawings, specify the materials, the fasteners, the fastening schedule… all that jazz.

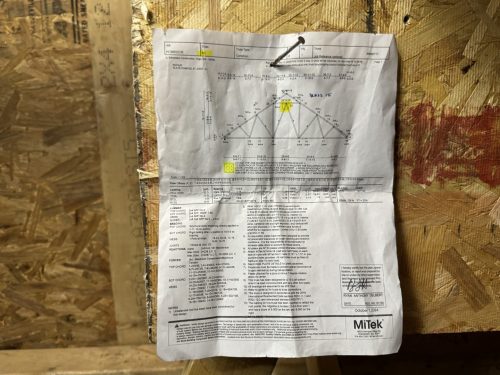

So we told our client as much, and the client rightfully pushed back on their builder. The builder took our advice, went back to the truss manufacturer for instructions, and repaired the trusses properly. We inspected the repairs for a second time, and they finally got it right. The photos below show substantial reinforcement to the trusses, along with the truss manufacturer’s repair instructions tacked all over the attic.

That’s more like it, eh? We chatted with the builder’s rep on site during our third visit to the property, and he admitted they “half-assed” the repairs the first time around—their words, not mine.

This story alone ought to be enough to convince you that every new construction home should be inspected, and every attic made accessible for inspection. But I’m just getting warmed up.

While we’re on the topic of attics, check out this loose bath fan duct, and the resulting frost that has accumulated in the attic. And now imagine what a mess this would be a decade from now.

Here’s a smashed dryer transition duct, which will severely compromise the performance of the clothes dryer.

Here’s another one.

This flexible furnace ductwork was damaged. It needs to be replaced.

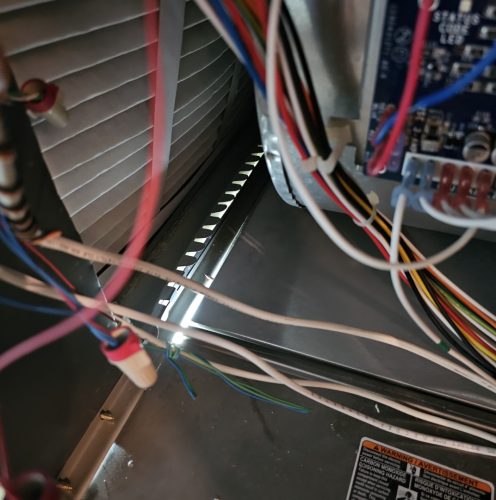

The ductwork needs to be sealed tight all over the house, but this builder missed a huge gap where the return ductwork connects to the furnace. This will bring a ton of unfiltered basement air directly into the furnace, and cause an imbalance in pressures. It’s pretty obvious when you open the blower door on the furnace and put a flashlight underneath the offending area.

This house has a toe-kick heat register below the kitchen sink, but no heat comes out of it… because there’s no ductwork connected to it.

This furnace closet was tough to access because the track for the overhead door blocked the doors.

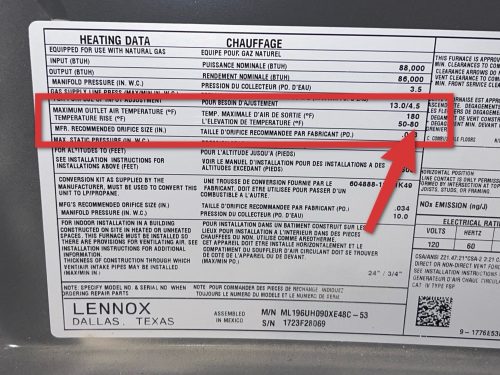

I tried to make most of the photos in this post new and fresh, not just the same old stuff we find every year. But after reviewing a ton of reports from the past year, I saw this same issue repeated so many times that I need to share it again. This is a furnace operating way outside of the manufacturer’s specifications. The temperature rise for this furnace should fall somewhere in the range of 50° – 80°.

If the inside temperature is 70°, we expect the supply air temperature to be in the range of 120° – 150°. But we measured the air at 180°. That’s way too high.

The most likely cause of this condition is sloppy ductwork; bends made too tight, kinked ductwork, and insufficient return air. It’s beyond the scope of a home inspection to determine exactly what the issue is, so we always recommend repairs when we find this because it can lead to comfort issues, short-cycling of the furnace, service calls, and premature failure of the furnace.

This furnace has the vent intake and exhaust terminals installed backward at the exterior. This makes the exhaust gas blow against the house, and some of it will get sucked back into the furnace. These gases are very corrosive and will shorten the life of the furnace.

Here’s a gas leak I personally found while attending an inspection with someone on my team. It wasn’t a huge leak, but it was enough for me to smell the gas while standing in front of the furnace.

One of the more recent electric code changes required GFCI protection at several 240-volt appliances, including wall ovens in kitchens. We’ve found many ovens that don’t seem to be compatible with 240-volt GFCI breakers because they constantly trip when we test them. This is currently a very common problem with new construction houses.

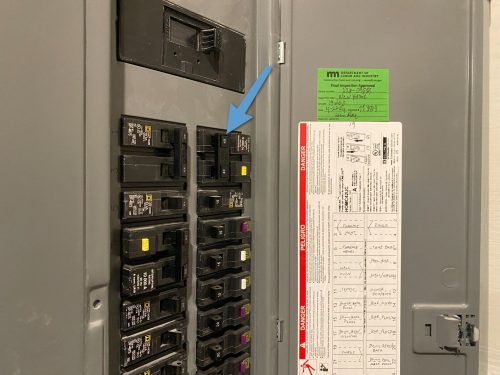

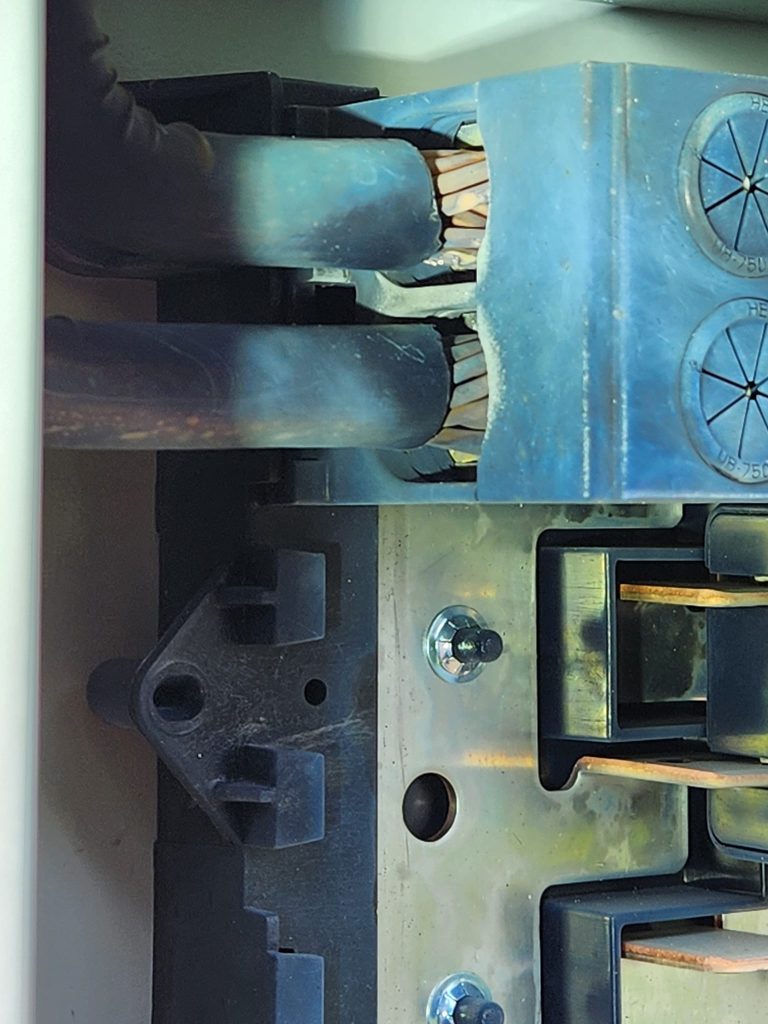

Something bad happened inside of this panel. We didn’t do it.

Outlets are no longer required at kitchen islands, but this thoughtful builder still provided a power source to the island in case someone wants to add outlets in the future. Unfortunately, they forgot to terminate the wires inside a box.

We constantly find plumbing vent test caps in place. These are installed so the plumbing system can be pressure tested for leaks. After the testing is finished, someone needs to go on the roof and remove the caps or cut them off. You wouldn’t believe how often this gets forgotten about.

And for the record, these aren’t situations where the builder will be dutifully coming back to remove the caps at the last minute. We find plenty of these on one-year warranty inspections too.

We’ve found leaking dishwashers.

Leaking showers.

Leaking tub spouts.

Leaking water heaters.

The long story on the water heater pictured above is that it’s actually the temperature and pressure relief valve leaking. This is happening because there’s a check valve on the water supply coming into the home, and the plumber failed to install an expansion tank, which is required if a check valve is present.

This improper kickout flashing consists of a scoop that directs water back up under the shingles. Fix it.

And finally, here’s a one-year-old building with a whole lot of missing fascia wrap.

Conclusion

My message remains the same: always get a home inspection, even with new construction. If you hire a good home inspector, you won’t regret it.

Continue reading:

- New Construction Defects 2023

- New Construction Defects 2022

- New Construction Defects (2019)

- Mega-post of Construction Defects (150+ photos)

- New construction inspections: before closing or before the one-year warranty walk-through?

- Either they lied about the HRV or they don’t understand what they did wrong

Patrick

November 20, 2024, 10:43 am

great article, always is funny when people think they dont need a inspection on a new build.