Minnesota adopted a new state plumbing code on January 23rd, 2016. We’ve always had a home-grown plumbing code, but for the first time, Minnesota has adopted a national plumbing code – the 2012 UPC – along with our standard list of amendments. The Minnesota amendments to the 2012 UPC can be found here https://www.revisor.mn.gov/rules/?id=4714, but it’s all fairly useless information without the 2012 UPC. Thankfully, there’s a single book that combines the 2012 UPC along with the Minnesota amendments, which can be purchased here: Minnesota State Plumbing Code Book. This code is also available online for free in pdf format here: 2015 Minnesota State Plumbing Code.

I’ve paged through the new plumbing code, and there are a ton of changes. I couldn’t possibly identify every change that has been made, but I’ve put together a list of some noteworthy stuff that stuck out to me. Most of these are changes, but some of them are simply wording changes that make things a little more clear. This new code is certainly easier to read and understand, as far as I’m concerned. If I have any of these changes wrong, please email me or leave a comment.

There are some sections that I haven’t yet figured out how to interpret, such as a new annual testing requirement for backflow prevention assemblies (603.4.2). I’ll probably follow up with one or more blog posts later on this year, discussing some of these changes as I learn more about them. The text in italics below are partial quotes from the new plumbing code.

The word “sillcock” has been replace by “hose bibb”

The word “sillcock” has been replace by “hose bibb”

The old Minnesota plumbing code referred to outdoor faucets as “sillcocks”, so that’s the language I frequently used in blog posts and home inspection reports, in an attempt to be consistent. I can’t find the word “sillcock” anywhere in the new plumbing code, so I’ll be calling them hose bibbs from now on.

General Rules, Hangers and Supports (T313.1)

The rules for hangers and supports have changed a ton. Besides the spacing changes, plastic pipes that convey waste from dishwashers or similar hot water wastes no longer need to be supported on continuous metal or wood strips. See Table 313.1

Shower drains must be 2″ (408.4)

The minimum size for shower drains used to be 1-½”.

Showers shall have a waste outlet and fixture tailpiece not less than 2 inches (50 mm) in diameter.

Shower doors must be at least 22″ wide (408.5)

The old plumbing code didn’t specify the minimum width for a shower door.

Shower doors shall open so as to maintain not less than a 22 inch (559 mm) unobstructed opening for egress.

Flood testing is required for showers (408.7.1)

My guess is that this requirement is only for shower receptors built on-site, but it’s not clear. The code says that showers need to be flood tested by filling the shower with water to the level of the rough threshold. It’s not clear how long this test needs to take place for, but I’ve been told that it’s a minimum of twenty-four hours.

Shower receptors shall be tested for watertightness by filling with water to the level of the rough threshold. The test plug shall be so place that both upper and under sides of the subpan shall be subjected to the test at the point where it is clamped to the drain.

Annoying shower designs are no longer allowed (408.9)

Annoying shower designs are no longer allowed (408.9)

Ok, maybe I’m paraphrasing just a bit here, but that’s really what it comes down to. From now on, the shower needs to be designed so one needn’t take a shower to test the shower.

Control valves and showerheads shall be located on the sidewall of shower compartments or otherwise arranged so that the showerhead does not discharge directly at the entrance to the compartment so that the bather can adjust the valves prior to stepping onto the shower spray.

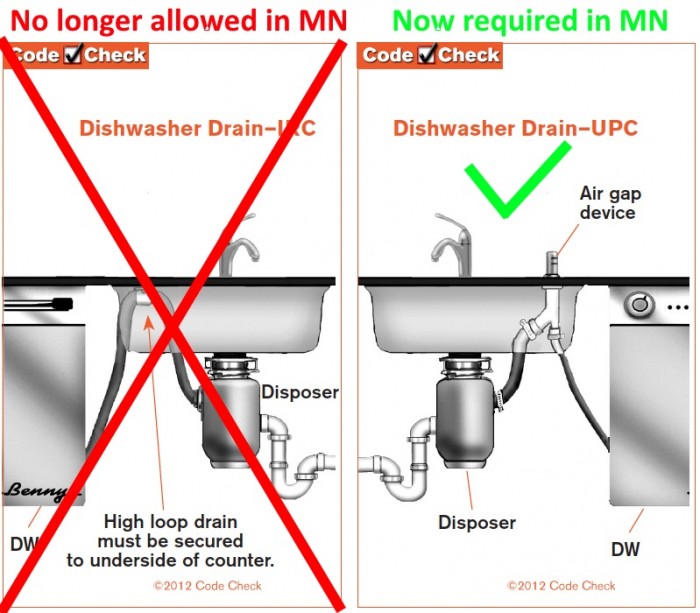

Hideous air gaps are required for dishwashers (807.4)

You read that right (and yes, I paraphrased again). Air gaps are now required on dishwasher drains. I don’t know how plumbing inspectors will be enforcing this new requirement, but the plumbers I’ve talked to say that an air gap will be required any time a dishwasher is installed or replaced. Sorry, but yuck.

The diagrams above were supplied by the fine folks at Code Check, who gave me permission to mark them up.

No domestic dishwashing machine shall be directly connected to a drainage system or food waste disposer without the use of an approved dishwasher air gap fitting on the discharge side of the dishwashing machine. Listed air gaps shall be installed with the flood-level (FL) marking at or above the flood level of the sink or drainboard, whichever is higher.

Emergency drain pans required for water heaters that could cause problems (507.4)

When a water heater is installed above an area where a leak would cause major damage, an emergency drain pan is now required. Section 507.5 of the code also prohibits the relief valve from discharging into this drain pan. This won’t affect most Minnesota homeowners, because most water heaters are installed on a concrete floor in the basement.

Where a water heater is located in an attic, attic-ceiling assembly, floor-ceiling assembly, or floor-subfloor assembly where damage results from a leaking water heaters, a watertight pan of corrosion-resistant materials shall be installed beneath the water heater with not less than ¾ of an inch (20 mm) diameter drain to an approved location.

Flex connectors are allowed on water heaters (604.13)

Flex connectors are allowed on water heaters (604.13)

A very strict interpretation of the minimum allowable pipe diameter prohibited the use of flex connectors at water heaters in the old code. Not so any more.

Flexible metallic water heater connectors or reinforced flexible water heater connectors connecting water heating to the piping system shall be in accordance with the applicable standards referenced in Table 1401.1. Copper or stainless steel flexible connectors shall not exceed 24 inches (610 mm).

Copper tubing can no longer be directly connected to galvanized steel pipes (605.17.1)

When dissimilar metals are connected to each other and water passes between them, a galvanic reaction can occur, causing the less noble metal to corrode. I know this is a big deal in some parts of the country, but not here in Minnesota. I usually see connections between galvanized steel and copper holding up just fine over long periods of time, but they’re no longer allowed. To connect copper tubing to threaded pipe joints, there must now be a brass adapter, a 6″ brass nipple, a dielectric fitting, or a dielectric union used. There’s quite a bit of text to this code section, so I’m not going to quote it here.

Relief valve discharge tubes may be listed, acceptable materials are clearly defined (608.5)

There has been much discussion over what constitutes acceptable materials for relief valve discharge tubes, but the new plumbing code makes it quite clear. Piping and fittings that make up the discharge tube may be made from galvanized steel, rigid copper tubing, CPVC, or polypropylene -or- the discharge tube may be a listed relief valve drain tube.

Relief valves located inside a building shall be provided with: (1) a drain that is not smaller than the relief valve outlet and piping and fittings made of galvanized steel, hard-drawn copper, CPVC, or PP; or (2) a listed relief valve drain tube with fittings.

Unions are required on water heaters (609.5)

Unions are required on water heaters (609.5)

Unions makes it far easier to replace a water heater, and now they’re required. It used to be acceptable to simply solder copper tubing into place on a water heater, which meant that replacing a water heater always required cutting and soldering new copper tubing for the water lines, but a union makes for a quick and easy disconnection point that only requires a pair of wrenches.

Unions shall be installed in the water supply piping not more than 12 inches (305 mm) of regulating equipment, water heating, conditioning tanks, and similar equipment that requires service by removal or replacement in a manner that will facilitate its ready removal.

Water piping for sillcocks hose bibbs must be at least ½”

The old Minnesota plumbing code required ¾” piping here. See Table 610.3

Purple primer is required on PVC joints (705.7.2)

This is trivial, as the old code simply required primer of a contrasting color. But still. Go Purple.

Where surfaces to be joined are cleaned and free of dirt, moisture, oil, and other foreign material, apply primer purple in color in accordance with ASTM F 656.

The maximum distance from a toilet to a vent is 6′ (T1002.2)

The old code allowed a maximum of 4′. See note 2 in Table 1002.2

That’s all for now. One change that everyone had probably been hoping for was the allowance of air admittance valves. These are allowed by the IRC, but not by the UPC, which is what was adopted. Air admittance valves are still not allowed in Minnesota.

Please contact your local building official with any questions about interpretations, as my opinion doesn’t mean squat.

Author: Reuben Saltzman, Structure Tech Home Inspections

Links: DW Air Gaps

Debbie Nelson Scheffler

March 8, 2016, 8:44 am

Does the air gap required for replacement dishwashers usually mean a new sink too? I wonder how home warranty companies will be addressing that. It is all in the fine print, I guess.

Reuben Saltzman

March 8, 2016, 11:24 am

I would assume not; it might require a change to the faucet, or removal of a soap dispenser.

Erik

March 14, 2016, 12:08 pm

Thanks Reuben for helping the Twin cities local tile industry by promoting “Flood testing” of all shower pans. Here in the twin cities I find so many failed tile showers its scary. We are typically testing our Brand new installs for 48-72 hrs. And welcome inspections. The inspectors love it when the walk into a flood test in progress.

more info here: http://www.tundrafinishworks.com/2014/09/shower-pan-flood-testing.html

Reuben Saltzman

March 14, 2016, 12:59 pm

@Erik – good for you guys. You’ve been doing it right all along!

greg mizer

April 20, 2016, 6:56 am

Are they going to require a check valve for your main water waste line if you replace it

Eva

April 25, 2016, 10:30 am

Hi Reuben

I came across your old blog about the drainage set up for dishwashers. I had my kitchen redone three years ago and there is a flexible hose that comes through on the top part of the side panel that separates the DW from under the sink I keep having a problem with food particles on my dishes and glasses in spite of rinse agent and I clean the DW with vinegar and Baking Powder every few months . So the drainage pipe comes out on top and kind of meanders across the back of cabinet and then goes up to connect to sink drainage . I think this is my back up problem . Should I have the flexible hose come down to the floor or close to it then back up above connection to sink for air hole ? I live in NJ BTW. Thank you for any help

Reuben Saltzman

April 25, 2016, 1:41 pm

Hi Eva,

I don’t follow. You said “there is a flexible hose that comes through on the top part of the side panel that separates the DW from under the sink“, and “the drainage pipe comes out on top and kind of meanders across the back of cabinet and then goes up to connect to sink drainage“.

Does that mean it looks like the drain in my diagram? If not, I recommend fixing it. If so, that’s not your problem.