Fiberglass batts are a poor choice of insulation for most applications, yet this still seems to be the insulation of choice for most handy homeowners. I’m been complaining about fiberglass batts for a while now, and for good reason.

Fiberglass batts are a poor choice of insulation for most applications, yet this still seems to be the insulation of choice for most handy homeowners. I’m been complaining about fiberglass batts for a while now, and for good reason.

Fiberglass batts are more expensive. I stopped by the Maple Grove Home Depot and compared the prices of unfaced fiberglass batts, loose fill fiberglass, and cellulose. Here’s what I found:

$0.93 / square foot for R38 Fiberglass Batts

$0.56 / square foot for R38 Loose Fill Fiberglass

$0.30 / square foot for R38 Cellulose

Side note: Comparing prices at Home Depot was a pain in the butt. Are they doing this on purpose? The sign on the fiberglass batts said “That’s only $0.93 sq. ft.” Yes, for R38… perfect. But then the sign on a bag of loose fill fiberglass says “That’s only $0.51 sq. ft.” FOR WHAT? You have to get out a calculator and do a little math to figure out this is for R30. What really drove me nuts was the sign for a bag of cellulose insulation, which said “That’s only $0.15 sq. ft.” Again, FOR WHAT? I got out my calculator, and determined that they’re quoting the price for R19. How are consumers supposed to make any reasonable comparisons when the three different prices per square foot are for three different depths? These signs are worse than useless, they’re misleading.

Fiberglass batts take more time to install. To be installed properly, fiberglass batts need to be painstakingly cut to fit the exact size of the space that they’re supposed to fill. Here are a few examples:

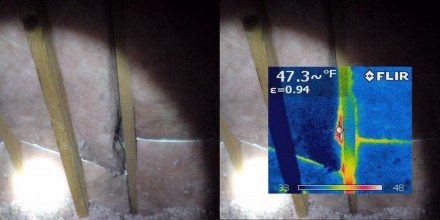

- A 2×6 wall that has electrical wire running perpendicular to the studs; should you push the insulation in front of or behind the wire, leaving a void in the insulation? No. You would need to cut the batt so it gets installed above and below the wire. The images below show the original photo on the left, and the photo with a thermal image overlay on the right. As you might guess, the red areas are warm.

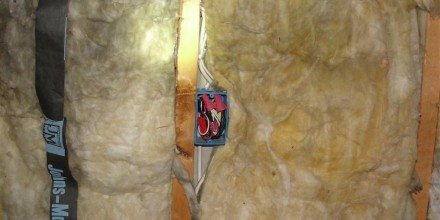

- A 2×6 wall with electrical outlet boxes; should you stuff the insulation around it, leaving nasty gaps around the box? No. You would need to cut out a rectangle in the batt so it fits around the outlet box without being compressed, and you would need to install a thin piece of fiberglass behind the outlet box.

- An attic with a bazillion electrical boxes, wires, pipes, truss chords, etc…; should you stuff the insulation around all of these obstructions, significantly reducing the insulating value? No. You would need to make a bazillion cuts and fits in the fiberglass batts to fill all of the gaps and voids.

The alternative to making all of these cuts and fits is to use something that fills in every little gap and void, such as loose fill fiberglass or cellulose in the attic, dense pack cellulose in walls, and spray foam at rim joists. These methods take far less time.

Fiberglass batts are extremely difficult to install properly. As you read through the examples above, you were probably wondering who would ever take the time to actually do all of these things. My experience has told me no one. I can’t say fiberglass batts are impossible to install properly… but I have yet to find fiberglass batts installed properly in an attic. All of the little voids that are left in fiberglass insulation equate to an exponential level of heat loss. The photos below came from a five-year-old custom built home in Edina that I inspected.

Fiberglass batts are itchy. I can touch the stuff with my hands and I’m fine, but once that stuff gets on my forearms, it’s bad news. My skin gets red, bumpy, and itchy. Even if you’re just walking on it, the fibers get released in to the air and they float for a long time. Your skin doesn’t even need to make direct contact with it to be affected. This makes fiberglass nasty stuff to work with or be around.

So why are fiberglass batts still used today? For small jobs, such as re-insulating a wall or two, it might not make sense to hire an insulation contractor to fill the walls with dense pack cellulose, and it’s not cheap to have spray foam installed. As for attics, again, there is no special equipment needed to install fiberglass batts. To blow loose fill fiberglass or cellulose, a huge insulation blower and hoses are needed, so it turns in to a fairly large project. It’s far easier to buy a few rolls of insulation at the store, drive ’em home in your car, and roll them out in the attic.

If you have an upcoming insulation project, I suggest using something other than fiberglass batts. In the near future, I’ll post a blog discussing all of the alternatives to fiberglass batts.

Reuben Saltzman, Structure Tech Home Inspections – Email – Edina Home Inspections