Joist hangers are metal brackets that support deck joists. It’s almost impossible to build a deck without them, and there is a ton of stuff that can go wrong with the installation. Today, I’ll cover the most common defects we find as home inspectors. Simpson Strong-Tie® is the largest manufacturer of these products, so I’ll reference their standards.

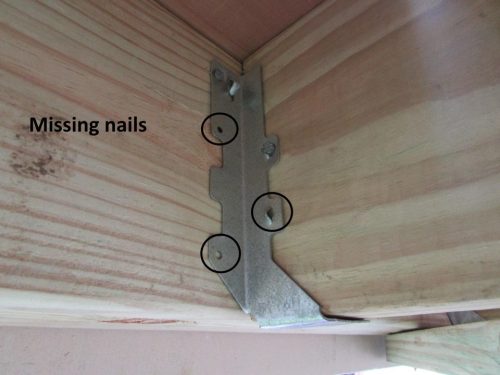

Missing Nails

Every hole in a joist hanger needs a nail. When nails are missing, the hangers won’t hold as much weight as they should.

The fix is simple: add nails.

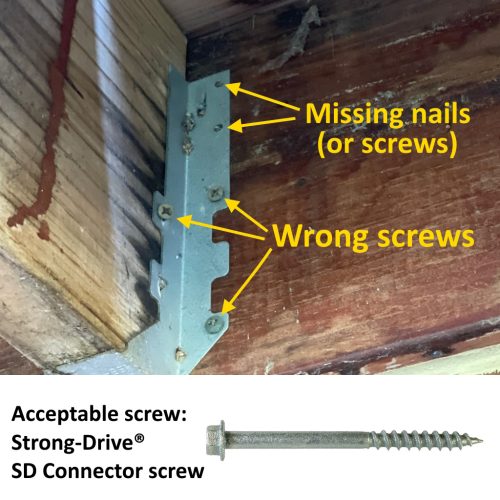

Screws used instead of nails

Joist hanger manufacturers specify nails. Screws don’t have enough shear strength.

The only exception to this is when you’re using a structural screw specified by the manufacturer, such as the Strong-Drive® SD Connector screw, pictured above. If I see a screw with anything other than a hex head, I know it’s wrong.

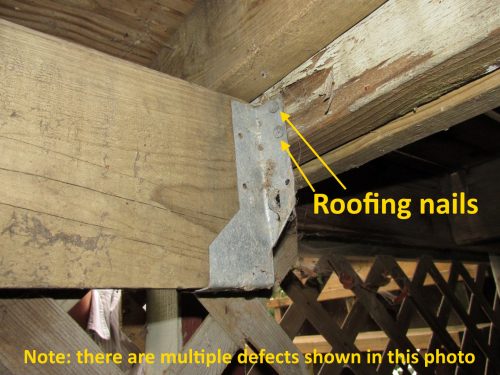

Wrong nails

Manufacturers specify full-sized 10d nails for almost everything. Sometimes we find other nails, such as roofing nails.

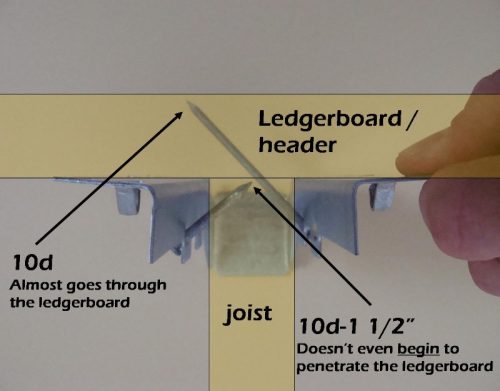

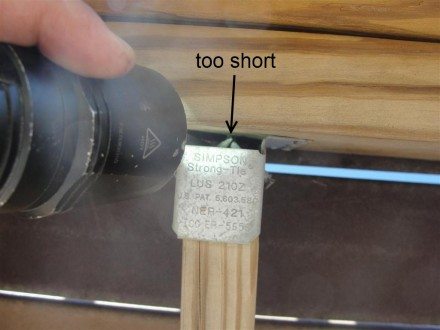

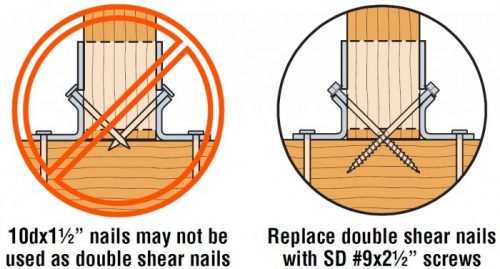

Other times, we find 10d 1-1/2″ nails used for cross-shear nailing. The image below shows the difference between a 10d nail and a 10d 1-1/2″ nail.

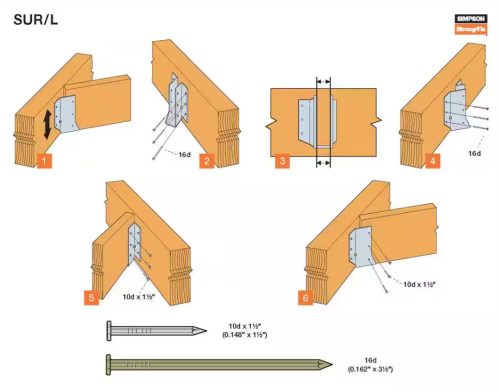

Those short little nails are made for joist hangers that have nails going directly into a joist; they’re short so they don’t come through the opposite the other side. But most joist hangers today require cross-shear nailing, where a 10d nail is supposed to go through the joist at an angle and secure it to the ledgerboard, as shown below.

One easy way to know if the nails are too short is to look underneath the joist. In many cases, there’s a gap between the joist and the ledgerboard, and you can see the tips of the nails.

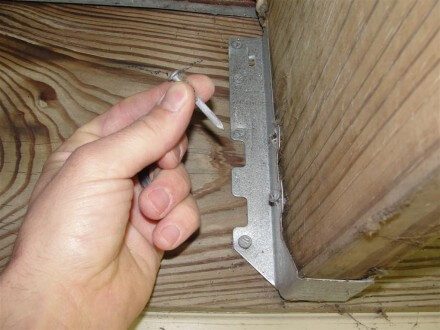

Another way to figure this out is to pull a nail out. If the wrong nails are used, they’ll pop out quite easily with a mini pry bar, like the one pictured below.

If the right nails are used, this little pry bar won’t do squat. The fix is to remove the wrong nails and install Simpson’s #9×2½” SD Connector screws.

Click the following link to see the full document: Repair of LUS Joist Hangers Installed with 10dx1-½” Nails. This document also lists the newly calculated load capacities, which I can’t imagine myself ever using as a home inspector. I leave that stuff up to the engineers.

Wrong hangers

Joist hangers can be designed for traditional dimensional lumber or manufactured joists. The hangers for these different types are joists are not interchangable.

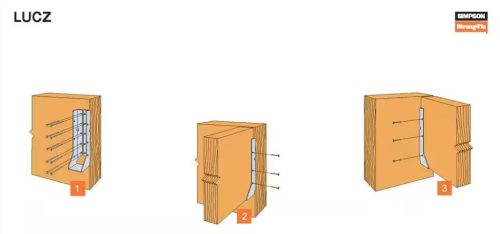

And if you have joists coming into a ledgerboard at an angle, you need to use a skewed hanger like those shown below.

You can’t just take a standard hanger and kinda, sorta make the joist fit.

Lack of full ledgerboard

The entire hanger needs to be installed against a ledgerboard. You can’t leave half of it hanging out in space.

Hangers need to be installed against a ledgerboard, not siding.

Damaged hangers

If you want a joist hanger installed at the end of a deck, you can’t just bend the end of the hanger by 90° and put nails into the end of the ledgerboard.

You need to use a special hanger on the end with concealed flanges, as shown in the diagram below or the photo above.

Undersized hangers

A joist hanger must be at least 60% as large as the joist. A 2×6 hanger can accommodate a 2×8, a 2×8 hanger can accommodate a 2×10, and a 2×10 hanger can accommodate a 2×12. Here’s a small chart with the math already worked out:

| Hanger size | Hanger height | Divided by 60% |

Max dimensional lumber

|

| 2×4 | 3.125″ | 5.2″ | 2×4 (3.5″) |

| 2×6 | 4.75″ | 7.9″ | 2×8 (7.25″) |

| 2×8 | 6.625″ | 11″ | 2×10 (9.25″) |

| 2×10 | 7.8125″ | 13″ | 2×12 (11.25″) |

Rusted hangers

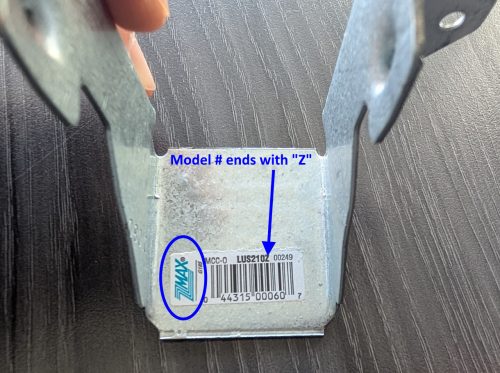

The treated lumber we’ve used for the last 20 years has chemicals that eat through steel, so you can’t use a standard joist hanger.

Hangers designed for contact with treated lumber will be hot-dipped galvanized or stainless steel. Simpson has a line called ZMAX® with an extra-thick galvanized coating, and all of these hangers have a “Z” at the end of their model number.

Joist too far from ledgerboard

Joists should be installed with no more than a 1/8″ gap between the end of the joist and the ledgerboard. Larger gaps mean reduced load capacity. We don’t get whipped up about 1/4″ gaps, but the gaps shown below need professional repair.

Missing hangers

This one is pretty simple. Put ’em where you need ’em.

Summary

There’s a ton of stuff that can go wrong with a joist hanger. It’s a wonder we ever find them properly installed! No, I’m kidding. Most professional deck builders get all of these details right without even thinking about it, but many decks are built by… other people. They keep us home inspectors on our toes.