One of the most common defects we find with asphalt shingles is improper nailing. Manufacturers of asphalt shingles give specific instructions on how to fasten shingles, and they’re all about the same. Unfortunately, following those instructions seems to be a difficult thing to do. The two most common nailing defects we find with asphalt shingles are overdriven nails and improperly located nails.

Overdriven Nails

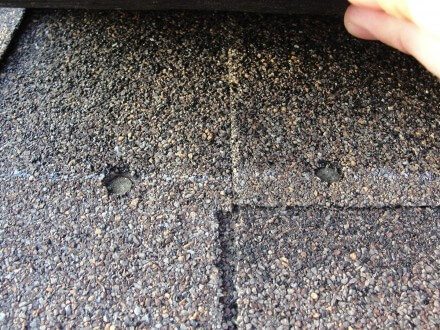

Most roofers use pneumatic nail guns to nail down shingles. When the pressure is set too high, the nails get driven into the shingles too far, plain and simple. When the nails are overdriven, the heads of the nails punch right through the mat of the shingle. This voids the shingle manufacturer’s warranty and greatly increases the potential for shingles to come loose and blow off, possibly in sheets.

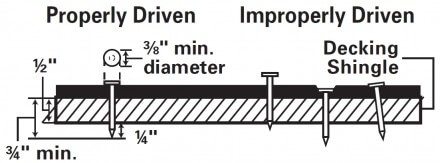

The diagram below shows what proper and improperly driven nails look like.

The photos below show several examples of overdriven nails.

Improperly Located Nails

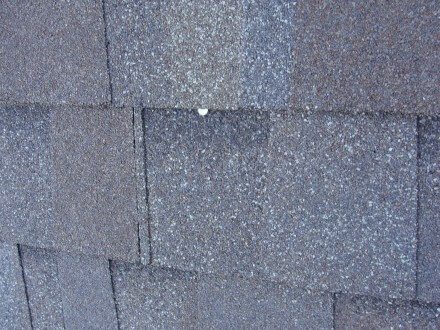

The other most common nailing defect we find with asphalt shingles is improperly located nails. The two most common issues are nails located too high or too low on a shingle. When nails are located too low on a shingle, it’s an obvious defect anyone with a good eye can often spot from the ground. This is probably why we don’t find this defect all that often; it’s just too obvious for most roofers to leave uncovered.

This defect can go on for a long time with no adverse effects, but there’s a good chance that any exposed nail will eventually lead to a roof leak. The photos below show a 14-year-old roof with one exposed nail. It took a long time, but this eventually caused a leak, which stained the finished ceiling below.

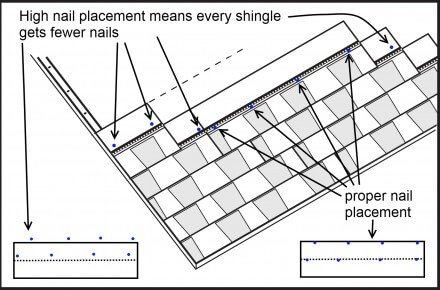

The more common and problematic nailing problem is to have nails located too high on the shingle. There is a fairly narrow strip on every shingle where you’re supposed to place the nail. When you do it right, the nail will actually catch the top edge of the shingle below it, meaning every shingle gets a nail through it in the middle and at the top. When nails are located too high on the shingle, they never catch the shingle below, which effectively cuts the number of nails going into each shingle in half. Hopefully, my diagram below will help to illustrate this; the blue dots are supposed to be nail heads.

The photos below show examples of high nailing. Yes, I know what I did there.

When shingles are improperly fastened, they have a tendency to slide and rip out of the nails holes, and this won’t be covered by the manufacturer’s warranty.

When the entire roof covering is installed like this, there is no simple fix. Either the new buyers need to accept the fact that their roof will be prone to having shingles blow off, or the roof covering will need to be repaired or replaced. For new construction homes, my recommendation is to have the manufacturer provide a letter explaining

These installation defects can’t be seen from the ground, nor can they be spotted with a drone. For this reason, you shouldn’t expect most municipal inspectors to identify these issues; it’s outside the scope of their inspection. I wrote about this topic here: Who Inspected Your Roof? If you want a thorough roof inspection, hire a home inspector who walks roofs.