For the last two weeks I’ve blogged about HRVs. In part one, I covered what HRVs are for and how they operate. For part two, I covered HRV maintenance and operation. Today I’ll discuss installation defects.

The most common defect I find with HRVs is that they were never balanced. When most HRVs are installed, a technician needs to balance the system to make sure the air getting exhausted is equal to the air coming in. If more air comes in than what goes out, you’ll have a pressurized house, which causes excessive air leakage out of the house at the upper floors. When more air goes out, the house becomes depressurized, which causes a host of problems with houses, including problems with fuel-burning appliances. Neither of these conditions are good for the home.

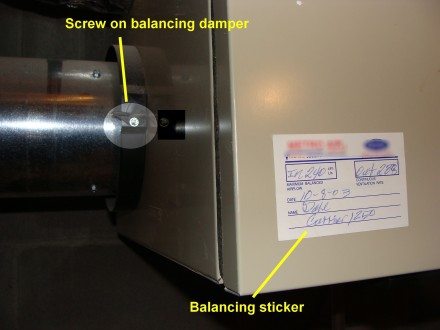

To make sure an HRV is balanced, I look for a balancing sticker and I check to make sure that the balancing damper controls have been screwed in place. If they’re not screwed in place, a balancing sticker means nothing. If I don’t see a balancing sticker, I don’t make a big deal about it, but I’ll often make a note in my report that it’s missing. If there are balancing dampers present but no balancing screws, I recommend having the HRV professionally balanced.

Most HRVs are installed hanging from straps or chains and springs to minimize the transfer of any annoying vibration from the fans. If an HRV gets mounted to the wall, I check the installation manual to make sure that this is an acceptable installation, and I listen on the other side of the wall to see how loud it is. Some aren’t designed for this type of installation, and they can be very noisy.

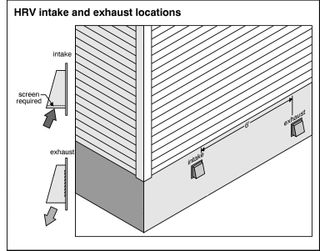

As a rule of thumb, the intake and exhaust locations at the exterior of the home should be located at least six feet away from each other. This is to prevent the stale air from getting sucked back in to the house. The intake must be located at least ten feet from any sidewall vented gas appliances, such as a powervent water heater or high-efficiency furnace. The intake should also be located at least ten feet away from anything smelly, such as where the garbage containers are kept.

The ductwork that feeds the intake from the exterior and exhaust to the exterior needs to be properly insulated. If it’s not properly insulated, you’ll feel an obvious cold draft.

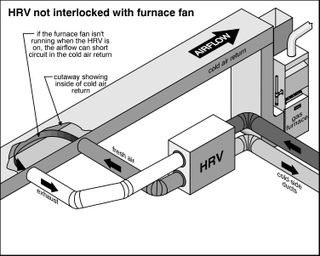

If the HRV ducts are only attached to the furnace’s return air, they must be at least three feet away from each other, and the furnace’s blower fan must turn on with the HRV to prevent the air getting added to the house from short-circuiting and getting pulled back out of the house. HRV manufacturers recommend connecting the furnace’s blower fan to the HRV for optimal performance, but it’s not always a requirement.

Every HRV needs to be plugged in to an outlet. If the HRV is running off an extension cord, this is an improper, unacceptable installation. Repair requires the installation of an outlet.

That concludes my list of the most common HRV installation defects, and that concludes this mini-series on HRVs. Thanks for reading!

Reuben Saltzman, Structure Tech Home Inspections – Email – Home Inspector in Maple Grove