What should home inspectors looks for when we find adjustable steel columns? We recently shared a few photos of some adjustable steel columns on our Facebook page, and this kicked off a great discussion about these columns. It made me realize that there are a lot of rumors out there about what is and isn’t acceptable, so I’m putting together a summary of what we ought to be looking for as home inspectors. There was a fantastic article published on this topic for home inspectors in the ASHI Reporter back in February of 2006 by Arlene Puentes, and is now available on her website at https://octoberhome.com/articles/adjustcolumn/adjustcolumn.html. I won’t attempt to re-create that article; I’m just hitting the high points here.

Two Column Types

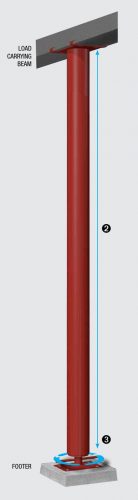

There are two flavors of adjustable steel columns, and they both have a screw and a plate on one end to fine-tune the exact length of the column. One type is a solid column with just a screw. The diagram below from Tiger brand shows an example of this:

Section R407.3 of the International Residential Code (IRC) says that steel columns “shall be not less than 3-inch-diameter”. To the best of my knowledge, all one-piece steel columns are at least 3″ in diameter. These are approved to use as permanent supports.

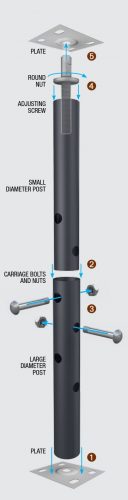

The other type is a two-piece column, also known as a telescopic column. These have two pieces of metal that are similar in diameter, but one is slightly smaller than the other. The diagram below, also from Tiger, shows an example of this:

These types of columns are less than 3″ in diameter, which means they’re not approved for permanent support. They should be considered temporary supports or possibly “additional” support. Besides not being code-approved for permanent support, manufacturers will tell you the same thing about their products. Tiger says “Telescoping jacks should be used as additional support, not the primary means of support.” These are handy to use as temporary supports when structural repairs at taking place.

As a home inspector, the question you should ask yourself is “Is this telescopic post necessary?”

When we find telescopic posts installed in places where permanent structural support is clearly needed, we recommend repair. The photo below shows a good example of this, as permanent support is clearly needed for this stairway.

On the other hand, we frequently find telescopic posts installed to provide additional support, and we evaluate these on a case-by-case basis. If a floor appears to be originally constructed and properly supported, yet someone added a telescopic post in a place where it doesn’t appear to be needed, what should we say? This is a judgment call. We always point out that these telescopic columns aren’t meant to be used as permanent support, but we don’t always make a big deal about it. The photo below shows a good example of this:

The floor framing all appears to be in good condition, so why was this added? If you removed that support, what would happen? Surely nothing. Perhaps the homeowner wanted to reduce some of the bounce in their floor. I don’t consider this to be a big deal… but you’ll get conflicting opinions on this. Some home inspectors and some municipal inspectors take a hard-line stance on two-piece columns. These home inspectors may call for professional repair, and these building officials may require complete removal or replacement with permanent posts.

Let’s look at another example:

This beam appears to have a proper wood column installed, however, the column also appears to have sunk approximately 1-1/2″, which may indicate a failed footing. The steel columns were likely added after the fact, and they don’t appear to have any footings, but there are big chunks of concrete to help distribute the load. Is this adequate? I don’t know. At this point, I’d punt to a structural engineer to have them put their blessing on this installation or recommend repairs.

I’ve gone through three examples; one where support was clearly needed, one where it surely wasn’t needed, and another where I didn’t know. As home inspectors, these are the various situations we face on a day-to-day basis, and the answers aren’t always black and white.

Adjustment screw: up or down?

Should the adjustment screw be located at the top or bottom of the steel column? It depends. To know for sure, you need to read the ICC-ES report.

What’s an ICC-ES Report? According to the International Code Council, “An ICC-ES Report is a document that presents the findings, conclusions, and recommendations from a particular evaluation. ICC-ES Reports verify that new and innovative building products comply with code requirements. ICC-ES Reports provide information about what code requirements or acceptance criteria were used to evaluate a product, and how the product should be identified, installed and much more.”

Tapco brands Tiger and Akron say the adjusting screw must be installed at the base, and after installation, the screw must be encased in concrete to prevent movement. On the other hand, AFCO “Zip” columns allow the adjustment screw to be installed at the top or bottom of the post. If the threads are left exposed, they must be damaged to a length of 1-1/2″ with a cold chisel or screw driver to prevent adjustment after it has been installed.

In short, adjustment screws should either be encased in concrete or damaged to prevent tampering.

Inspect the top and bottom plates

The top and bottom plates need to be secured in place. The photos below show examples of this. The column that’s fastened at the top surely could have used some washers, but whatever. We’re just happy to see lag screws.

It goes beyond the scope of a home inspection to determine the structural adequacy of any individual column, but we can definitely check to make sure that everything is plumb, level, and straight. The photo below gives a great example of an unhappy column with a bent top plate. That alone would be enough for me to recommend further inspection and repairs, but this was also a two-piece column and it wasn’t fastened at the top. And the beam was twisted.

It doesn’t get much more obvious than this, right?

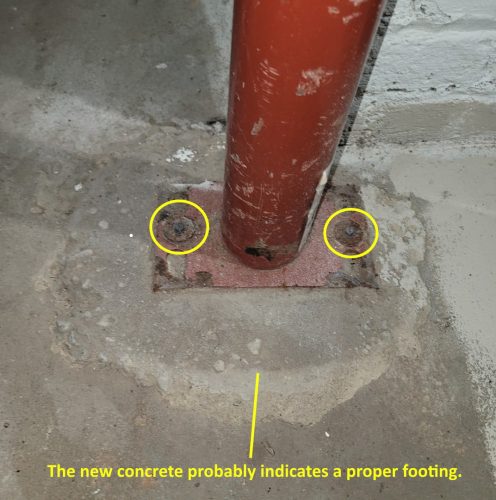

Also, inspect the bases of any steel columns for signs of rust or deterioration. The column below had a severely rusted base, and it appeared to be installed directly on the basement floor, not over a footing.

If a column has more than just a small amount of surface that can be easily scraped off, it should be replaced. And while we’re picking on this one, note how much of the steel threads are exposed. The maximum allowable that I’ve found is 4″. This looks like it could be more than that.

Summary

Two-piece steel columns shouldn’t be used as permanent support, one-piece columns are fine. Some manufacturers allow the threads to be up or down, others say the threads should be down and encased in concrete. The top and bottom plates should be fastened in place, and everything should be plumb, level, and intact.

George Benigno

March 1, 2022, 7:29 am

Always informative and educational for all who work in the trades, those who inspect and even the homeowner who eventually has to foot the bill. Thank You all at Structuretech I have learned so much and continue to.

Margaret Conable

March 1, 2022, 10:35 am

I have a question about this. The main body of the one-piece column is greater than 3″, but the screw section looks like more like 1 1/2″ or 2″. Doesn’t that short section become the functional diameter of the column? Also, the bearing surface becomes the surface of the threads on the threads, right? I don’t get why adjustable columns of any type are allowed. I guess I’m one of those hard liners…

Reuben Saltzman

March 1, 2022, 10:44 am

Hi Margaret, adjustable posts are acceptable because they’ve gone through the ICC evaluation process to prove that they’ll do what they’re supposed to do. They’ve been tested and put through the wringer. Check out https://icc-es.org/evaluation-report-program/ for more information about exactly what goes into these reports.

As for your specific questions about how much weight can be supported by threads, I’d turn to the manufacturer’s published information.