Gas water heaters are a lot like decks, in the sense that most handy homeowners feel qualified to install one. Thanks to these handy folks, we find more installation defects on decks and water heaters than just about any other component in the home, and today I’m going to share how we inspect water heaters. I’ll start with the stuff that’s common to both gas and electric water heaters, then move onto specifics for those different types. I’ll cover the inspection of tankless water heaters in a future blog post, and testing draft at water heaters in yet a different post.

Temperature and Pressure Relief Valve

To help prevent a malfunctioning water heater from turning into a missile, they all come equipped with temperature and pressure relif valves. Mythbusters made a cool video showing what could happen without one of these safety devices, which you can see below.

While Adam and Jamie do these experiments in style, the Watts company was doing these same experiments as far back as 1939.

In short, these safety valves are important. To help prevent this valve from shooting scalding hot water or steam into someone’s face, the Minnesota State Plumbing Code (Sections 507.5 and 608.4) requires a discharge pipe to be attached to this valve. A few requirements for this pipe are as follows:

- Must be full sized. This almost always means it must be a 3/4″ pipe.

- Must terminate within 18″ of the floor (and 6″ for the rest of the country).

- Must not be threaded or capped at the end. If it were threaded at the end and the valve started leaking, some handy homeowner might screw a cap onto the end, thus disabling it.

- Must be made from galvanized steel, rigid copper, CPVC, PP, or be a listed tube. This means no PEX.

Improper Gas Piping

The installation requirements for gas piping that leads to water heaters is the same as any other gas appliance, but again, I find more problems at water heaters than at any other gas appliance. Here are a few basics that we look for:

- There must be an approved gas valve installed within six feet of the water heater and in the same room, or at a manifold.

- There must be a way to disconnect the gas piping to the water heater after the valve. This could be through the use of an appliance connector or a union. The idea is that you need to be able to shut off the gas to the appliance and be able to disconnect the appliance without shutting off gas to the entire house.

- There must be a sediment trap installed just before the water heater. A sediment trap is required to help prevent little impurities in the gas piping from fouling up the appliance.

Improper Water Piping

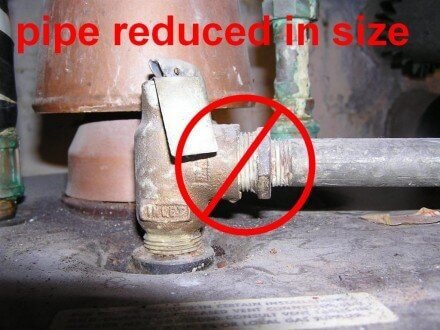

- The water pipes must be at least 3/4″.

- There must be a shutoff valve installed on the cold water supply pipe that feeds the water heater. A common myth is that there should never be a valve on the hot water side, but this is perfectly acceptable.

- The first 18″ of water piping going into and out of the water heater can’t be PEX (604.13).

- The cold water line must be connected to the cold water side. If this is installed backward, it will make it seem like the water heater runs out of hot water very quickly.

That wraps up my list of the most common installation defects. What about venting? I’ll have to cover that in a separate blog post. There’s simply too much to talk about. This isn’t an all-inclusive list of the requirements for a water heater, but it probably covers 95% of the installation defects we find during home inspections in the Twin Cities. For a video showing a water heater replacement from start to finish, check out this water heater replacement video which I shot back in 2016.