If you own a newer home or you’ve recently had gas lines added to your home, there’s a good possibility that Corrugated Stainless Steel Tubing, or CSST, was used. This is a relatively new material that is approved for the distribution of natural gas inside of homes. The best analogy I can think of to describe this material is that CSST is to steel gas pipes what PEX is to copper tubing, or Romex® is to rigid metal conduit.

CSST needs to be bonded. The most common issue that home inspectors find with CSST is a system that hasn’t been properly bonded. When CSST is installed without being properly bonded to current standards, there is an increased risk for damage to the material from a nearby lightning strike. When CSST is damaged, it can leak gas and cause an explosion and/or a fire. To the best of my knowledge, all manufacturers of CSST began implementing specific bonding requirements around 2007. Of course, proper bonding won’t make CSST immune to damage from a nearby lightning strike, but it will reduce the risk of damage.

What about existing installations? Building codes have something called ‘grandfathering’. This means that if something was installed to code, it’s still a code compliant installation today, even if the codes have changed significantly. The nice thing about being a home inspector is that we don’t need to get hung up on code requirements. If something is deemed unsafe due to a change in accepted residential construction standards, our Standards of Practice require us to recommend repair.

If CSST was installed to code in 2005 and the manufacturer didn’t have any special requirements for bonding at the time it was installed, the installation still meets code… but that won’t stop a home inspector from recommending the system be bonded to today’s standards. The manufacturers of CSST have changed their installation requirements because they’ve learned that the old methods weren’t good enough.

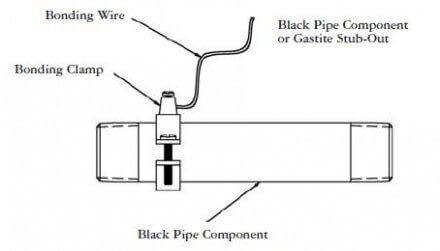

What does proper bonding look like? All manufacturers of CSST require the systems to be bonded in a specific manner – there needs to be a separate ground wire connected either to the rigid gas piping before the CSST, or directly to one of the CSST nuts. The diagram below shows an example of what this would look like when properly installed to today’s standards.

The photo below shows an example of CSST bonded at the exterior of the home, with the bonding clamp connected to the CSST nut.

The video below, produced by Gastite, shows a couple examples of how to properly bond CSST.

Note: some second generation versions of CSST, such as CounterStrike, do not have any additional bonding requirements.

How would you know if you had CSST in your home? Look for flexible tubing with a yellow jacket that covers the ridges. It’s doesn’t have to be yellow – for instance, CounterStrike has a black jacket, but the majority of CSST in Minnesota has a yellow jacket. I’ve never seen any other color in person. This material is not to be confused with an appliance connector, which might have a yellow coating that follows the contours of the ridges. The photo below shows the two different materials.

The bottom line is that if you have a home with CSST, you should make sure it’s properly bonded to today’s standards, regardless of whether the installation ‘met code’ when it was originally installed. You can’t grandfather safety.

Additional Information on CSST and bonding

- Basics of CSST – a brief description, a brief history, and some basic installation requirements

- Alert: Jury Rules that CSST is a Defective Product in a Landmark Case

- CSST: Direct Bonding Required for All Brands

- Cutting Edge Solutions – this web site is filled with information related to CSST bonding requirements.

Post Edit 7/9/2013: The news clip below shows me talking with Kare 11 News about CSST bonding.

Reuben Saltzman, Structure Tech Home Inspections

Milind

August 28, 2012, 6:48 am

Great post…that was a maddening series of conversations.

bill

August 28, 2012, 8:29 am

These are the type of the posts by you that are really good, they could save lives or even “just” save a house from burning down.

Thank you for running your blog.

Photos from New Construction Home Inspections, Part II | Structure Tech Home Inspections

September 18, 2012, 4:01 am

[…] CSST gas lines are used, they need to be properly bonded to reduce the risk of fire from a nearby lightening strike. This doesn’t always […]

Sid

December 4, 2013, 1:25 pm

Can the copper grounding wire be bare or must it be insulated?

Also, can the copper wire be attached to the wooden header in the basement that sits atop the outside concrete block wall as its being strung to the electrical panel? (No risk of fire?)

Reuben Saltzman

December 5, 2013, 4:34 am

@Sid – yes, the copper wire can be bare. There is no risk of fire from this wire touching wood.

Sid

December 5, 2013, 6:02 am

Thanks Reuben. I read that you enjoy answering people’s questions (which is much appreciated), so here are a couple more:

1. Is there a special adapter I should use in one of the breakout holes in the top of the electrical panel enclosure to grip the grounding wire after it’s inserted into the opening, or will one that grips romex work okay?

2. I’m presuming that the grounding wire should be attached to the grounding bus bar inside the electrical panel where all the other grounding wires are attached, correct? I read somthing somewhere that seemed to suggest attaching the grounding wire to the neutral, but that didn’t make sense to me.

Thanks again for your help. Sid

Reuben Saltzman

December 5, 2013, 12:57 pm

@Sid – #1: no, nothing special is needed where the ground wire comes through the panel.

#2: yes, and the ground wires and neutral wires will actually all connect to the same bus bars.