I constantly see the rules about dryer duct safety and dryer transition ducts being brought into question, mostly on home inspector forums. If it’s tough for home inspectors to keep this stuff straight, it’s gotta be really tough for average homeowners. Products and rules are always changing, so if you read this post five years from now, be aware that things may have changed. Also, these are the rules for Minnesota. These rules come from section 504 of the 2020 Minnesota Mechanical Code. If you’re in a different part of the country where you use the International Residential Code, check out section M1502. The rules are nearly identical. This is not a complete list of those rules but a list of the most commonly violated ones.

Dryer duct vs. transition duct

Before I dig into the rules, I need to define the difference between a dryer duct and a dryer transition duct. A dryer duct runs through the house to exhaust the air from the dryer to the exterior. A dryer transition duct is a flexible section of duct material that allows the dryer to connect to the duct. The only place a transition duct should ever be found is between the dryer and the duct.

Rules for dryer ducts

Dryer exhaust ducts must vent to the exterior. There are UL-listed devices that will allow you to exhaust your dryer to the inside of your house, but that doesn’t mean you should. All of that moisture coming back into the home is bad news. Here in Minnesota, code section 504.1 makes it clear that dryers, whether gas or electric, need to vent to the exterior of the building.

Exhaust ducts must have a smooth interior finish and must be made from metal that is a minimum of 0.016-inch thick. This is approximately 27 gauge steel, but you’ll only find 26 gauge steel. The duct size must be 4 inches in diameter. No more, no less. If you oversize the duct you decrease the air velocity, which means you increase the potential for lint accumulation. Section 603.9 of the code says that joints in ducts need to be sealed with UL-181B foil tape or mastic; no duct tape, no screws (504.4).

The maximum length of a dryer duct is up to the clothes dryer manufacturer’s installation instructions. The code specifies a maximum of 35 feet and gives reductions for various elbow fittings, but the code is also extremely conservative. I’ve never seen a clothes dryer manufacturer give instructions nearly as restrictive as those given by the code, and the code allows the manufacturer’s requirements to be followed. I quickly searched the manufacturer’s requirements from Maytag, LG, Kenmore, and Samsung. They allow equivalent lengths of 64, 65, 64, and 80 feet, respectively.

The length of a dryer duct is measured from “the connection to the transition duct from the dryer to the outlet terminal“. In other words, you don’t count the transition duct when determining the duct length.

Each terminal requires a backdraft damper and no screens are allowed at the terminal because they get clogged. The worst is when screens are installed at roof terminals, because nobody ever goes up there.

Rules for dryer transition ducts

A transition duct is a short length of flexible material that is allowed to connect the clothes dryer to the duct. Nothing else. The requirements for dryer transition ducts are pretty short and sweet.

- Transition ducts must be a single length. This means no connecting sections together.

- Transition ducts cannot be concealed within construction. That means no passing through walls, floors, hidden spaces, etc.

- Transition ducts must be listed and labeled in accordance with UL 2158A, and they cannot be longer than 8 feet.

This last one seems to be a moot point because dryer transition ducts can’t be UL 2158A listed if they’re more than 8 feet long (at least I’m pretty sure about that, but I don’t own those standards to verify). But still, there it is. I stopped by a few big-box retailers to check out their offerings many years ago, and the labeling for the products agreed with all of this, but the labels weren’t completely clear. I tried to make it easy by giving a few of them the thumbs up or the thumbs down.

This first one is 25′ long, and it’s UL Listed for… something… I have not idea what… but it says on the package “NOT FOR USE IN DRYER VENTING”.

This next one is over 8′ long, and it’s not UL Listed, despite the package telling you is a dryer vent duct.

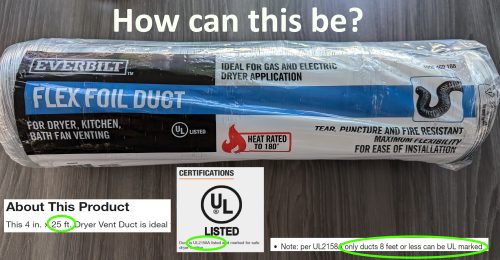

And this most recent find has me completely stumped and annoyed. It’s a 25′ duct, and the package says it’s ideal for dryer ducts, and it also says it’s UL Listed.

Huh? How can that be? I went to the product website, and I found these three pieces of information:

- The product is 25′ long.

- The product is UL 2158A Listed.

- UL2158A says that only ducts 8 feet or less can be UL marked.

So what gives??

These next few photos are self-explanatory.

Interestingly enough, several dryer manufacturers and a whole lot of home inspectors don’t like the flexible ‘foil’ type dryer transition ducts. Personally, I have no problem with them. If they’re kept short like they should be, they don’t cause problems. But they’re surely the worst legal product available.

I have several reasons to dislike the semi-rigid aluminum ducts that everyone else seems to love, however. To start with, there are two different flavors of these ducts; one is listed and the other isn’t. The listed ones are about twice the price, and the two are nearly indistinguishable. If not for the label, who could tell the difference between these two?

Not only that, but foil ducts will return to their original shape after being bent. Not so with the semi-rigid aluminum.

Side note: was the duct pictured above ever a proper installation? Click on the photo to see a larger version, and you’ll notice it has those little crimp marks going around it, just like the transition duct pictured above that is not UL Listed. In other words, it was probably never a proper installation.

Semi-rigid foil ducts are also dangerously sharp and should not be handled without gloves (ask me how I know). So does this mean I make a big stink out of exactly what type of dryer transition duct is used during home inspections? No. I verify that they’re properly installed and potentially of proper materials. That means no plastic.

The best clothes dryer transition duct money can buy

There’s a UL 2158A-listed clothes dryer transition duct out there that outperforms everything else that I’ve shown so far. It’s so superior that it should really have its own category, like “Super-Duper Transition Duct,” but it simply falls into the same category as everything else. It’s called DryerFlex and can be purchased at Home Depot, but not with the rest of the dryer duct material. You have to head over to the appliance accessories section of the store.

You’ll find it hidden in that department with a GE label on the box, but this is the DryerFlex product. It retails for about $25, and it’s well worth the price. It can also be purchased directly from Home Depot here. I blogged about this product back in 2012: http://structuretech1.com/dryerflex-a-superior-dryer-transition-duct/

If you want the best possible product for both performance and fire safety, I recommend this product.

Larry

April 18, 2017, 5:34 pm

Some good advice here. Its the little things that make the difference and this is one of them.

While we are in the laundry room upgrading to braided stainless water lines on the washing machine, or shutting the water off when not in use is also a good idea.

Wes Fahlenkamp

April 24, 2017, 12:04 pm

I’ve seen a lot of dryers that have a short straight shot to the outside, but for some reason the flexible transition looks like a snake coiled up behind the dryer. This ain’t good. It’s OK to cut it to length.

Also, in most of the new homes I work in, the dryer is put in the middle of the house, which means a very long vent run with a lot of elbows. Who’s cleaning these things so they stay efficient?

Kevin Wynn

July 23, 2024, 10:28 am

It’s not really difficult in a lot of applications to forgo transition duct entirely and just use dryer duct (smooth aluminum material) directly from the dryer outlet. It just takes a little careful trimming to fit.

Reuben Saltzman

July 24, 2024, 12:10 pm

Agreed.